Functional Safety Engineering

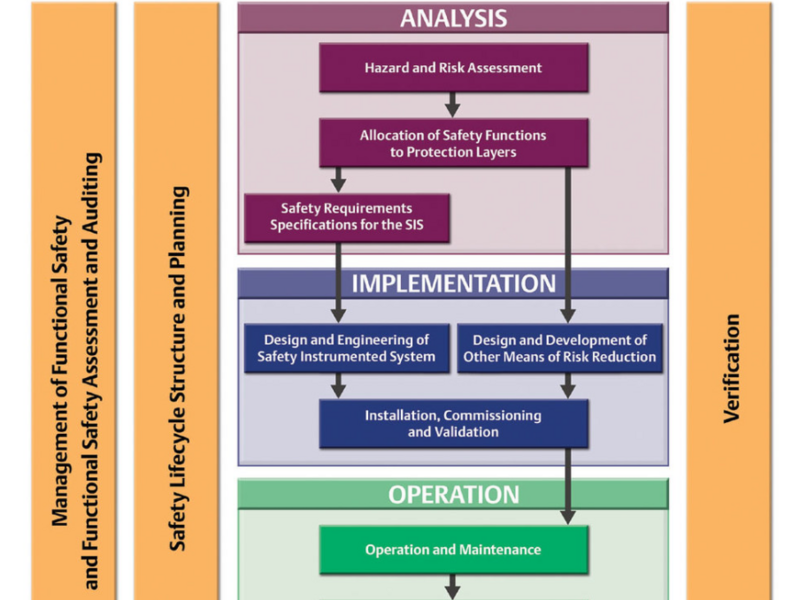

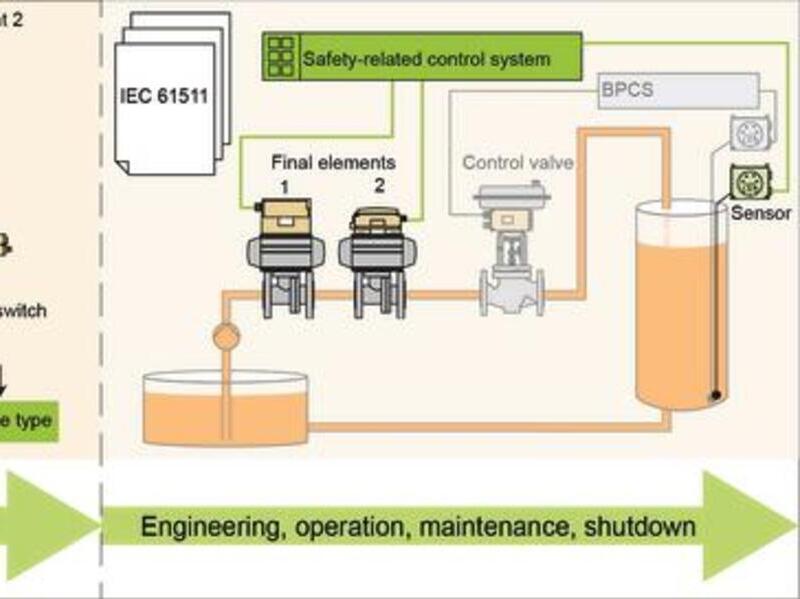

Implementation of Safety Instrumented Systems(SIS) is very critical in maintaining an environment which is safe for human lives and expensive assets. By preventing or mitigating failure events, SIS characterizes methods to reduce the likelihood of occurrence for hazardous situations. That’s why Functional Safety Engineering studies are done with the goal to achieve the required

protection for equipment, implementing adequate safety related systems to offer the appropriate level of risk reduction. Automize designs and evaluates safety systems in accordance with IEC-61508/61511/ISA-84.00.01-2004 regulatory standards.

Our team work hard to provide high-availability and seamless integrated solutions and produce deliverables that achieve your scope, schedule, and budget requirements. Functional safety is prerequisite of any company’s reputation, compliance, availability, reliability, and sustainability. Each year all plants spends a significant amount to maintain the functional safety lifecycle for plant, personal, equipment and environment safety. Our expertise comes handy when working with a safety system to risk reduction and minimize failure rates. Improper design, SIL determination or verification, and integration of SIS leads to personal and operation al hazard, along with high probability of unwanted shutdowns and increased failure rates.